World Class Manufacturing (WCM) is a business initiative with growth plans of 3 to five years, focused on Production Organizations.

Through the implementation of a series of defined processes and systems, WCM will allow greater operational efficiency and in this way will be able to sustain a reduction in costs, increasing the business margin and promoting future growth. Let's look at the following steps:

|

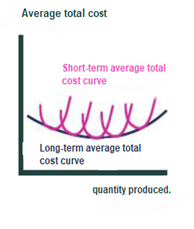

The JIT system is a tool that fine-tunes the production system, in other words, it dramatically reduces the response time of the total manufacturing or service time and on the other hand it does it at the lowest cost, this equals greater profitability. | |

|

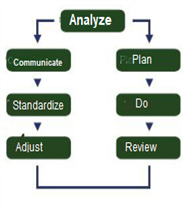

Daily Operations is the system we use to move from a reactive to a proactive workplace, through the use of standard work systems and rigorous review processes. Autonomous Maintenance is one of the core methodologies of the TPM process and also resides in Daily Operations. | |

|

Initial Engineering focuses on the design, construction, and implementation of the transfer of a production system with a vertical initial startup and sustainable performance. This involves an initial understanding, coordination, and management of all production requirements to minimize losses. |  |

|

Safety and Environment responsibility is part of everything we do, forming an integral part of WCM. |  |

|

Quality Maintenance is a proven WCM methodology that identifies the source of product quality defects in order to achieve greater stability throughout manufacturing operations. |  |

|

The tools lead to discovering the origin of the causes of problems in order to eliminate losses permanently. The Pillar works to support all functions of WCM to assist in the development of an improvement in the thinking and capabilities of all employees. |  |

|

Ensure that all employees are trained and qualified to perform within the new WCM environment. |  |

|

Working proactively to eliminate equipment breakdowns and build problem-solving capabilities is at the core of progressive maintenance. This means relying on WCM methods (including loss tracking and root cause analysis). |  |

If you want to receive articles like this by email, sign up! Click Here.

We invite you to watch the video on how our GESPLINE platform works: Click Here!