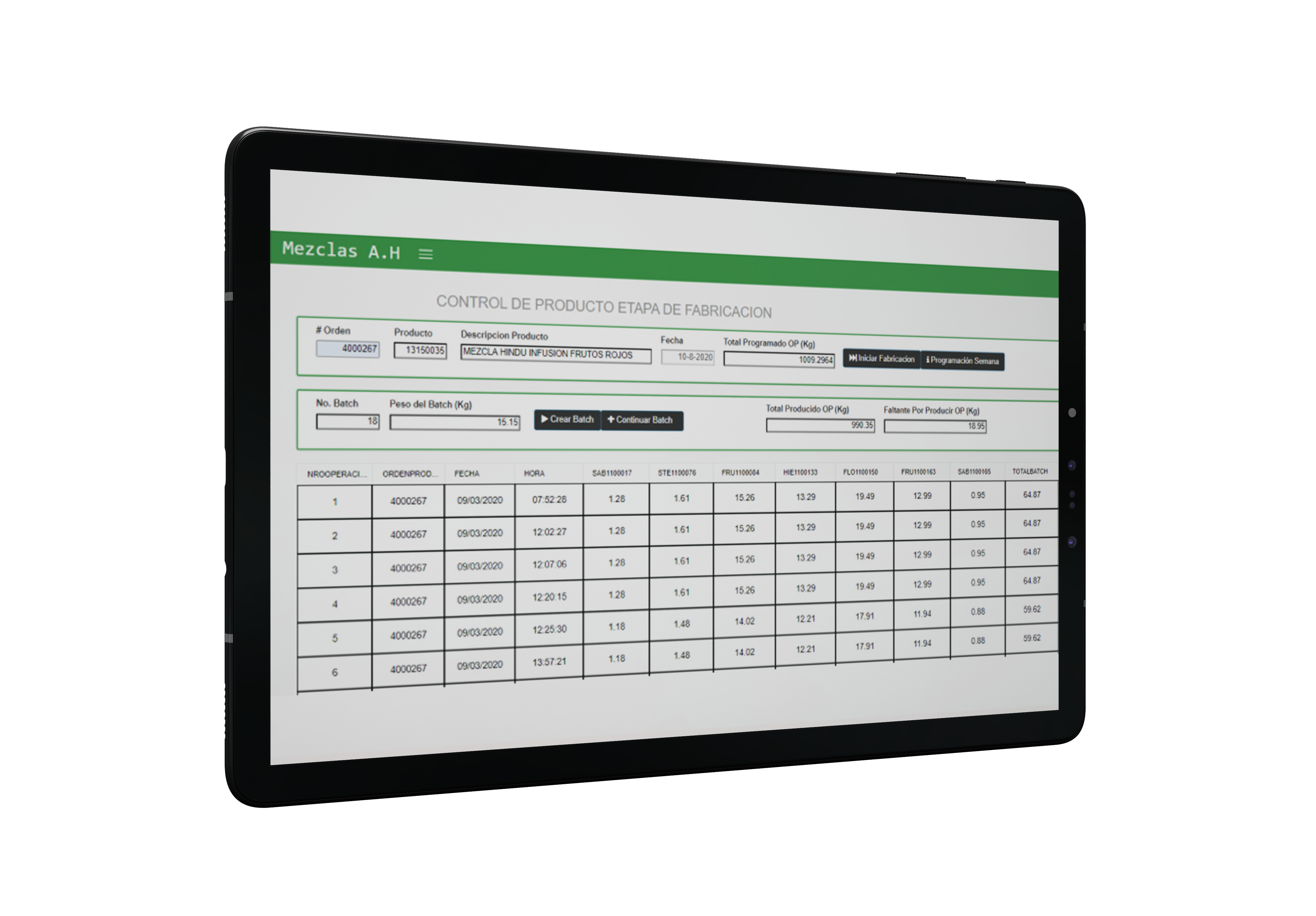

Transformation in Blend Manufacturing: Discover how the Recipe Module redefines precision in recipe dosing. Seamlessly integrating with your ERP, our software allows you to configure or take live recipes, ensuring that each ingredient is weighed accurately before blending. The Recipe Module is key to maintaining the consistency and quality of your products.

Ideal For: Food factories, soap industries, and other sectors where precise dosing is crucial, especially those that use manual methods.

The Recipe Module is an advanced software designed for factories that require meticulous precision in their blends. It allows for the weighing of each raw material according to the recipe, capturing the weight directly from the scales and balances in the plant, ensuring precise dosing in line with expectations.

To integrate the Recipe Module into your operation, you only need scales with communication ports and a touch panel for operator interaction. Our team will assist you at every step, ensuring a smooth transition and a significant increase in the efficiency and quality of your production. With the Recipe Module, take your manufacturing to the next level.

Copyright © 2024 Proalnet. Web design by Eddi.